The lathe spindle is a typical type of shaft component, which is one of the key components of the machine tool. It transfers the rotational motion and torque to the workpiece or tool through the furniture at the end of the spindle. Therefore, in work, the spindle needs to withstand torque and bending moment, and also requires high rotational accuracy. Therefore, the manufacturing quality of the spindle will directly affect the working accuracy and service life of the entire machine tool.

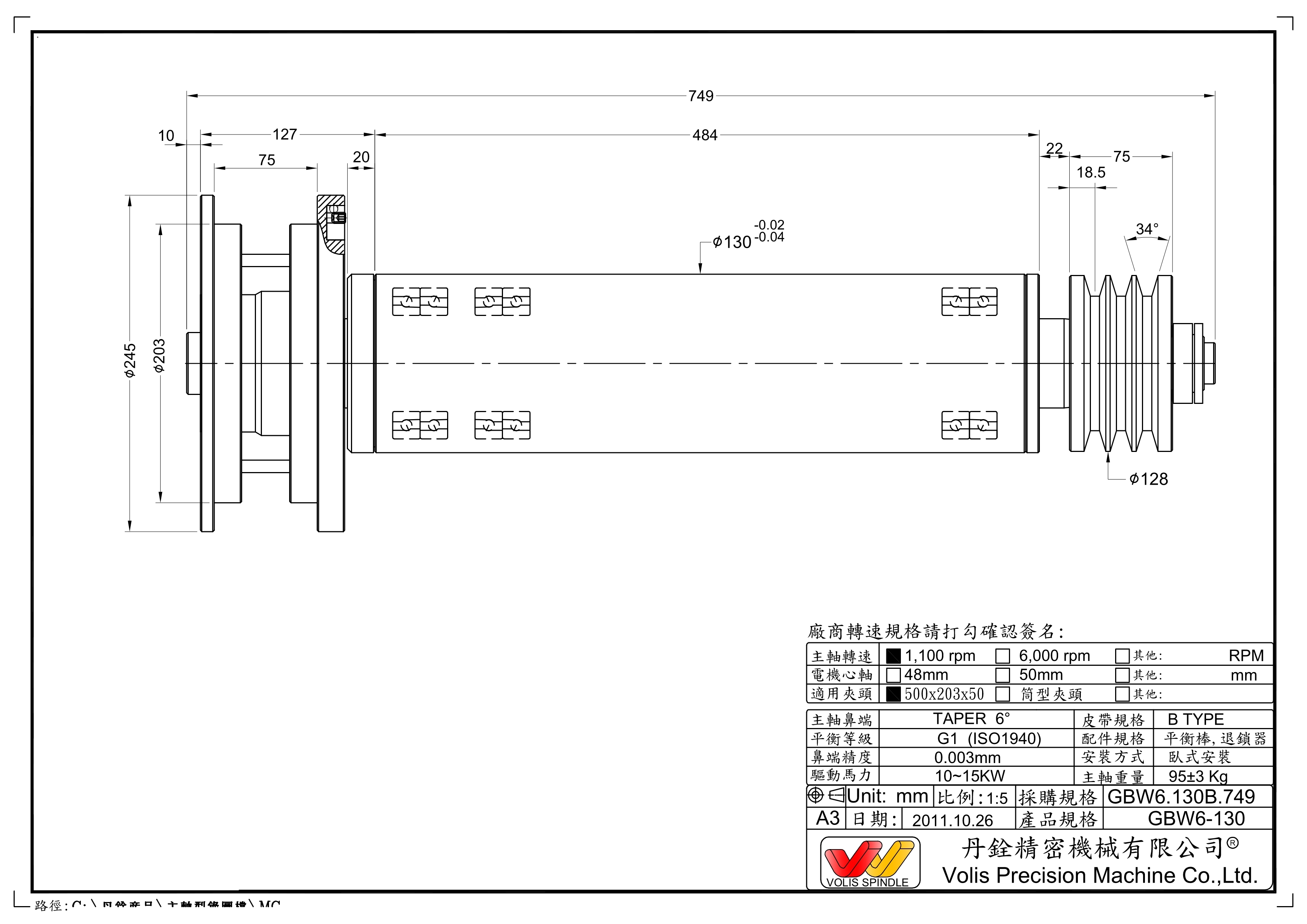

The lathe spindle refers to the axis on the machine tool that drives the rotation of the workpiece or tool. Usually composed of spindle components, bearings, and transmission components (gears or pulleys). In machines, it is mainly used to support transmission components such as gears and pulleys, transmit motion and torque, such as lathe spindles; Some are used to clamp workpieces, such as mandrels.

Working conditions of lathe spindle:

(1) Withstand alternating torsional loads, alternating bending loads, or tensile and compressive loads;

(2) Local (journal, spline, etc.) bearing friction and wear;

(3) Under special conditions, it is affected by temperature and medium.

current location:

current location: